For animal keeping facilities that have unique hygiene requirements, the feed may need to be specially treated to minimize microbial content.

Sanitation

Sanitation

For animal keeping facilities that have unique hygiene requirements, the feed may need to be specially treated to minimize microbial content.

Exposing the feed to high temperatures during the production process causes a decrease in microbial count. This reduction is much greater with extrusion than with pelletization due to the higher temperatures involved. However, for even greater hygiene requirements, such as for specific-pathogen-free (SPF) facilities, it may be necessary to take further measures to sterilize the feed. Processes such as autoclaving or irradiation will maximize the hygienic quality of the feed and at the same time extend its shelf life.

Exposing the feed to high temperatures during the production process causes a decrease in microbial count. This reduction is much greater with extrusion than with pelletization due to the higher temperatures involved. However, for even greater hygiene requirements, such as for specific-pathogen-free (SPF) facilities, it may be necessary to take further measures to sterilize the feed. Processes such as autoclaving or irradiation will maximize the hygienic quality of the feed and at the same time extend its shelf life.

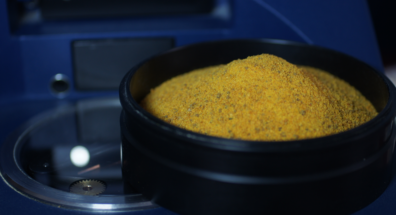

Autoclaving

Autoclaving is a process that uses steam to sterilize feeds with the goal to effectively reduce the microbial count. This involves exposing feed in an autoclave to high temperature and high pressure for a set period.

It should be noted that the availability of heat-sensitive components like vitamins or amino acids in feed is partly reduced during the autoclaving process. Autoclavable feeds from KLIBA NAFAG are adjusted in the concentration of sensitive nutrients to account for the loss during autoclaving and guarantee adequate nutrient levels.

Furthermore, the autoclaving of pelletized feed can lead to clumping or an increased pellet hardness. The technical processes in the production of autoclavable KLIBA NAFAG feeds are designed to maintain their physical appearance to a high degree.

Autoclaving

Autoclaving is a process that uses steam to sterilize feeds with the goal to effectively reduce the microbial count. This involves exposing feed in an autoclave to high temperature and high pressure for a set period.

It should be noted that the availability of heat-sensitive components like vitamins or amino acids in feed is partly reduced during the autoclaving process. Autoclavable feeds from KLIBA NAFAG are adjusted in the concentration of sensitive nutrients to account for the loss during autoclaving and guarantee adequate nutrient levels.

Furthermore, the autoclaving of pelletized feed can lead to clumping or an increased pellet hardness. The technical processes in the production of autoclavable KLIBA NAFAG feeds are designed to maintain their physical appearance to a high degree.

Irradiation

Irradiation similarly serves to reduce the number of microorganisms in feed. Feeds from KLIBA NAFAG are packaged in hermetically sealed bags and exposed to irradiation (X-ray) either in individual bags or on entire pallets. Microorganisms such as bacteria or viruses are inactivated during this process.

For successful irradiation, KLIBA NAFAG cooperates with a state-of-the-art independent and certified irradiation facility. KLIBA NAFAG feeds are irradiated only with X-ray to ensure an even distribution of the irradiation and a minimal impact on the feed. The irradiation procedures used for KLIBA NAFAG feeds are validated and strictly controlled. Irradiation certificates are provided for every batch.

Compared to autoclaving, irradiation results in less vitamin and amino-acid losses, prevents the clumping of pellets, maintains pellet durability, and permits a high level of consistency.

Irradiation

Irradiation similarly serves to reduce the number of microorganisms in feed. Feeds from KLIBA NAFAG are packaged in hermetically sealed bags and exposed to irradiation (X-ray) either in individual bags or on entire pallets. Microorganisms such as bacteria or viruses are inactivated during this process.

For successful irradiation, KLIBA NAFAG cooperates with a state-of-the-art independent and certified irradiation facility. KLIBA NAFAG feeds are irradiated only with X-ray to ensure an even distribution of the irradiation and a minimal impact on the feed. The irradiation procedures used for KLIBA NAFAG feeds are validated and strictly controlled. Irradiation certificates are provided for every batch.

Compared to autoclaving, irradiation results in less vitamin and amino-acid losses, prevents the clumping of pellets, maintains pellet durability, and permits a high level of consistency.